Specifications

| TECHNICAL FEATURES | ||

Max. panel dimensions | mm (in) | 3050x900x60 (120.0”x35.4”x2.3”) |

| Min. panel dimensions | mm | 200x70x10 |

| X-Y axes speed | m/min (ft/min) | 40 (1,575) |

| RO.AX DRILLING UNIT | ||

| Connection tools with cylindrical shank, | Ø mm | 10 |

| Max. tools diameter | mm (in) | 70 (2.75”) |

| Vertical spindles | n. | 12 (7X-5Y) |

| Horizontal spindles | n. | 2+2 (X) 2(Y) |

| Rotating spindles motor power | kW/Hp | 2,2/3 |

| Spindles speed | rpm | 3000-8000 |

| Fixed integrated disc cutter (direction) | X | |

| Max. diameter of disc cutter | mm (in) | 125 (4.9”) |

| Disc cutter rotating speed | rpm | 5.500 |

| ELECTROSPINDLE | ||

| Motor power (S6) | kW | 4,5 |

| Max. speed. | rpm | 24.000 |

| Manual tool changer | HSK63F | |

| Max. tool diameter | mm (in) | 20 (0.78”) |

| MINIMUM INSTALLATION REQUIREMENTS | ||

Compressed air consumption | Nl/cycle | 450 |

| Extraction air consumption | m³/h | 1900+550+300 |

| Exhaust air speed | m/sec | 30 |

| Installed motor power | kVA | 21 |

| Exhaust outlet diameter | mm | 150+80+60 |

| Usa- Canada Version Voltage /Frequency | 230V – 60HZ |

Design features

The highest performance drilling technology on the market is installed with the Ro.Ax (Roto-Axial) F18L drilling unit from Hiteco. Fewer and larger internal components mean the head can drill faster and more accurately and requires 10X less maintenance than other units. An inverter is included to boost drilling speeds up to 8,000rpm

Each panel can be automatically measured to check for variance in the length and width, eliminating the possibility of erroneous positioning of the machining operations on the finished panel

Made possible by the clamp holding design and the vertical worktable, the machine requires no operator intervention between batch 1 panels to set up the machine

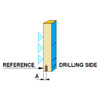

The highest quality of finished casegoods is maintained through intelligent design of the CX100. By drilling and routing on the top face of the panel any variance in panel thickness is disguised on the finished product