Specifications

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Expandable scoring blade

- Squaring fence with no. 3 LCD readouts for stops position

- Squaring frame with CompeX device

- 2-axis scoring unit with automatic adjustment

- Motor 9 kW Hz50 (11 kW Hz60)

| TECHNICAL FEATURES | ||

| Blades tilting | 90° ÷ 45° | |

| Max. saw blade diam. with scoring blade installed | mm (in) | 400 (15.75”) |

| Max. saw blade projection from table at 90°/45° | mm (in) | 140/97(5.5 / 3.81”) |

| Scoring blade diameter | mm (in) | 120 (4.75”) |

| Squaring stroke | mm (in) | 3200 (10.5’) |

| Cutting width on parallel fence | mm (in) | 1500 (62.94”) |

| Other technical features: | ||

| Three-phase motor | 11kW (15hp) 60Hz | |

| Exhaust outlets diameter | 120 (4.75”) | |

| MINIMUM INSTALLATION REQUIREMENTS | ||

| Power absorption | A | 42 |

| Voltage frequency | 230V 60Hz |

Design features

SCM Thundercut App for mobile devices: optimizer/sequencer even for not skilled workers

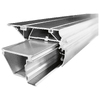

Optimal support also to larger pieces, with the sliding table 400 mm (15.75”) wide. The slideways, with special arch-ground steel profile (SCM solution), are secured with a procedure of aluminum riveting so that to ensure an exceptional precision and smoothness

Easy: maximum reliability due to the function pushbuttons and easy-to-use with the electronic control of up to 5 axes with the 7” LCD display, 16:9 format. These features translate into immediate improvements in productivity and guarantees the capability of the full potential of the machine

Sliding carriage: maximum cut quality guaranteed over time

The carriage will never require adjustment due to its structure with arch-ground steel slideways (developped by Scm).

The new "Eye-S" control panel, with its attractive design, allows easy and intuitive machine programming, combining the 10” colour touch-screen display and the Maestro “Active S” user interface.

The saw blade lifting of the saw unit is carried out by a sturdy cast-iron structure with sliding on ground round slideways which guarantee the best accuracy. The unit tilting is carried out on cast-iron rotation sectors in a crescent shape to ensure reliability over time.

Speed and precision ensured by the motorised programmable rip fence mounted on a recirculating ball screw mechanism with sliding on linear guides.

Speed and precision ensured by the motorised programmable rip fence mounted on a recirculating ball screw mechanism with sliding on linear guides. The fence can be overturned when extra-support for very large panels is needed.